A walk around a golf course often raises conversations among members, golfers and staff – because course conditions, the look of the course and the speed of the greens directly affect golfer enjoyment and course playability.

Many golfers do not realize what is necessary to cut greens at heights less than 1/8 of an inch. Many courses in Michigan are cutting their fairways shorter than 7/16”. Cutting turf that short and keeping it alive and disease free is a full-time job, but that is just part of the job – properly using and maintaining the right equipment is a huge part too.

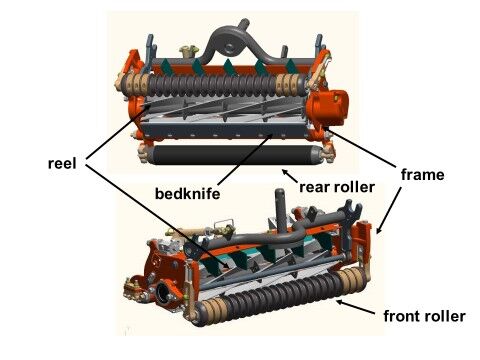

The equipment used for cutting the manicured areas of the golf course are commonly referred to as “reels” – the precision cutting instrument necessary to provide the conditions that today’s golfers enjoy and expect. They are made up of 5 main components (reel, bedknife, frame, rear and front rollers) and miscellaneous hardware.

The reel consists of a number of helix shape blades welded to supports and mounted to a shaft. This weldment is precision ground to be a perfect cylinder, supported in the frame by precision bearings held within the frame.

Below the reel is the bedknife, held to the frame by a mount bar that allows it to be adjusted parallel to the reel and adjusted into the reel blade to create a scissors type cut as the helixed blade slices across the bedknife. Anyone who has experienced cutting paper with loose scissors will understand the perspective of how an un-adjusted reel is cutting grass poorly.

Depending on the course, the reels are sharpened as little as once a year or as frequent as once a month, with adjustments happening in between. Most courses are adjusting the reel to bedknife daily. The more attention paid to the reel adjustment the better the reel mowers perform (cut) and the better quality of cut. This leads to healthier grass and a better after-cut appearance.

If the courses you play are well maintained, be grateful that someone there is paying attention to the details – just for you.

More information is at: www.migcsa.org

(Story author John Garlets is the Division Manager for Service and Parts at Spartan Distributors)